|

My name is Serhiy Kleimenov, and I set myself the task of creating a line of men's cosmetics that will combine classics, modern trends in men's fashion, and innovative developments in styling and care for everything that grows on our heads. It was not easy, but we managed. |

How did we do it?

1. We determined the assortment and consumer properties of each product. Therefore, only eleven products are in the line, but this is all a man should have on his bathroom shelf.

2. We found one of the best chemist-technologists in Ukraine, who agreed to take on this difficult task, even though she had no previous experience developing some products since no one had made them in Ukraine yet.

3. The exhausting process of preparing and testing laboratory samples began. Some products came out from 2-3 pieces, and some had to be processed 5-6 times. We clearly defined the technical task for each recipe, so the approval of the samples was uncompromising.

4. Formulation development and sample testing took less than a year. At first, I tested each sample on myself, and when I was satisfied with the properties, the product was tested by friendly friends and familiar barbers. The received feedback was processed, corrections were made to the formulas, and after receiving positive feedback from all sources, the recipe was approved.

5. The duration of recipe development is related to requirements for consumer properties and raw materials that will be used in further production. For the production of our products, we use only official and certified raw materials from such "giants" as BASF, Clariant, Gustav Heess, Biesterfeld, Cabot, etc. Yes, it is more complicated and expensive, but we will not skimp on this.

6. While the chemists were working on formulas, I selected containers. I didn't think it would be so exciting. We have eleven products; only a few can be filled in the same container, so we have eight different packaging types. We buy something in China; we order something from a tube plant in Ukraine; we purchase something on the domestic market.

But no matter where we buy the container, it is submitted to the laboratory for microbiological testing before starting production. Everything should be clean - this is important.

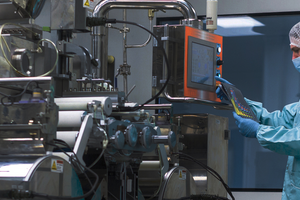

7. We don't have our factory yet, so our production partner is one of the Ukrainian enterprises. The experience of the chief technologist, the presence of the correct water filtration system, and the organization of the process according to Good Manufacturing Practice standards played an essential role in our selection. And then everything came together - with us again, an experienced, one of the best cosmetic technologists in Ukraine. According to GMP, an additional water purification system is installed at its factory, which prevents heavy elements from entering the product—and, of course, production. Of course, it was possible to "cook" cheaper, but this is not our case.